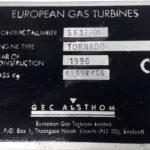

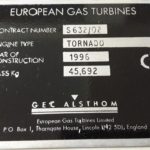

Tornado (SGT 200 ) European Gas Turbine

Tornado Gas Turbine SGT 200 is a 6.5 MW engine designed and developed in the late seventies and introduced into service in 1983 for industrial and petrochemical applications (Wood, 1987).

Tornado Gas Turbine can be used as a single-shaft version for electricity generation, and as a twin-shaft turbine for a mechanical drive.

Tornado SGT 200 operates with gaseous and liquid fuels. It provides high efficiency and an excellent power-to-weight ratio and is available as an industry-assembled package.

It has a unique and simple design with advanced technologies that can be primarily used as a compressor drive.

Tornado Gas Turbine Functions:

Air is drawn in through filters into the intake volume guide. Vanes direct the airflow through the fifteen stages axial compressor where the air is compressed by a ratio of 12.3:1.

The compressed air then mixes with fuel and continuously combusts to generate rapidly expanding gases that drive the compressor turbine.

The gas generator mechanically drives the power turbine in a single sharp configuration or by the exhaust gases from the gas generator in twin sharp configuration providing drive for an alternator turbo compressor or pump hot exhaust gases adducted away via an exhaust system and can be used to heat a boiler or steam generator.

Benefits of Tornado Gas Turbine SGT-200:

- Proven and reliable design

- Excellent fuel flexibility

- Long oil and gas heritage

- Mechanical drive application

- Dry Low Emissions (DLE) combustion system for low NOₓ emissions

- On-site and off-site maintainability

Tornado Gas Turbine SGT-200 Design Features:

- For Power Generation: Single Shaft

- For Mechanical Drive: Double Shaft

- 15 stages of compression

- Cannular combustion type

- DLE system

- 2 gas generator turbine stages

- 2 power turbine stages